Removing the TCO barrier

Utilizing one hundred years of label expertise and sophisticated engineering, Gallus One offers a complete digital label solution, including all the software and hardware necessary to produce high quality, profitable digital labels. All this, with the highest level of automation available, and the most competitive TCO.

Cloud based technology

Over the last few years, cloud technologies have positively impacted many industries around the world, accelerating productivity and driving sustainable and successful futures. With cloud capabilities in-built within Gallus One, you can not only enjoy remote set-up, but transparent performance monitoring and standardization across your press portfolio and manufacturing sites.

Elevate your business with Gallus Solutions

The Gallus One ecosystem

Workflow

Increased Workflow Efficiency

With Gallus One, the press and all its key systems have been designed to operate seamlessly together. What’s more, operation and control of the press can be made using, Prinect, which is both very intuitive and transparent – further ensuring maximum press efficiency and productivity. For additional flexibility, Prinect is also compatible with all other third-party workflow systems, so no need to change solutions depending on your existing set-up.

- Best in Class Color Management to create ISO profiles

- Color Center: Streamlined, efficient and automated quality assurance. Transparent documentation for ultimate production reliability

- Calculate ink usage offline and in advance, for precise order processing and better business planning — also remotely via VPN

Ink

High Performance Ink

The high performance Gallus One ink, developed by HEIDELBERG, is designed to deliver vibrant colors and increased stability and reliability – delivered quickly from a global organization with facilities in USA, Hong Kong and Japan.

Predictive Services

Predictive System Management

Identifying potential problems before they occur, is one of the Gallus One’s most important features – further safeguarding our market leading productivity. Utilizing cloud capabilities, the press communicates performance status as well as maintenance issues to the Gallus HelpDesk, which then ensures a prompt response as necessary.

- Reliable and continuous operation

- Less downtime and stoppages

- Scheduled maintenance

- Strict compliance with EU Data Protection Regulation — no personal data or order content is shared

Inkjet Technology

Highly Automated Inkjet Technology

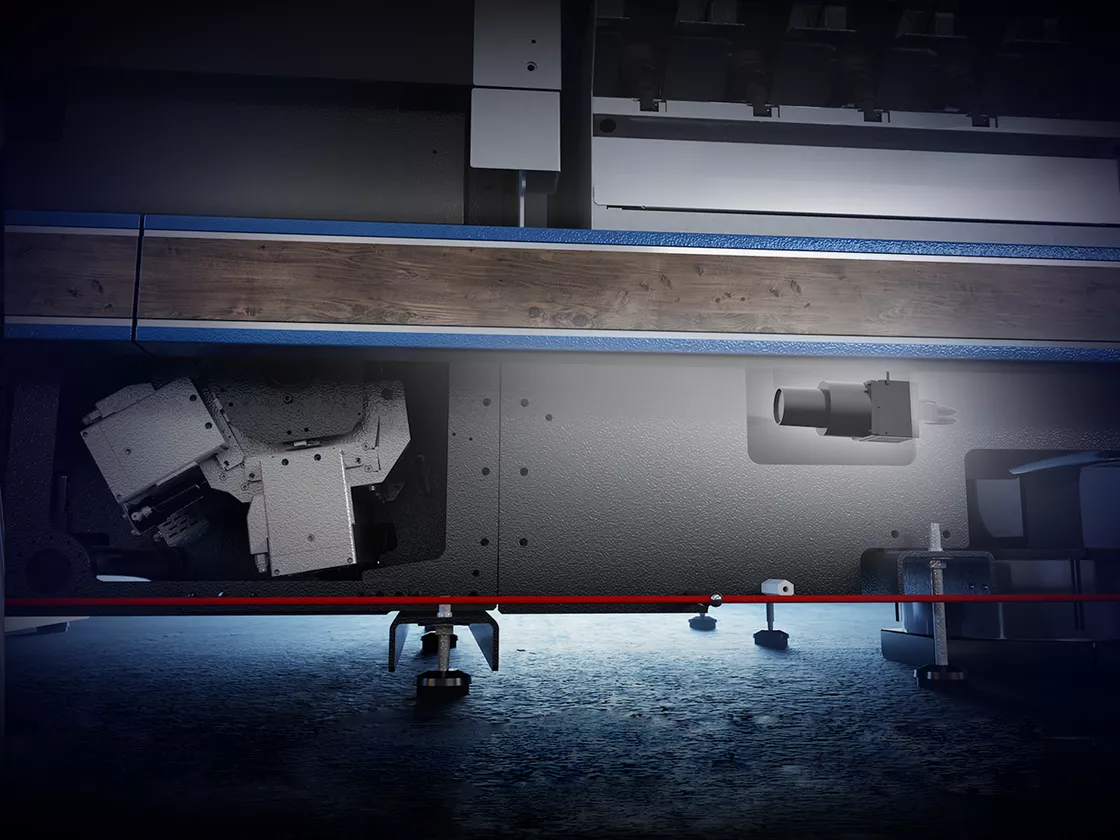

New Gallus One employs highly automated inkjet technology, that ensures precise ink application with high process stability. This enables the delivery of market leading print quality and reliability, all at high speeds, offering the maximum control over all process steps.

Press

The Gallus One — Robust & Reliable

The Gallus One is based not only on new latest cutting-edge technologies, but also on the proven platform and components of the Gallus Labelmaster Series – with hundreds of units in the field – as well as key elements from the market leading Gallus Labelfire 340, 1200 dpi printing press.

Gallus One features

With a compact footprint and a high level of automation, the new Gallus One is poised to drive the digital transformation, harnessing cutting edge features including:

HMI

Human Machine Interface (HMI)

The user interface of the Gallus One is designed to summarize the most important information at a glance. For quality assurance, the print results can be checked live, via web video, while the press is running.

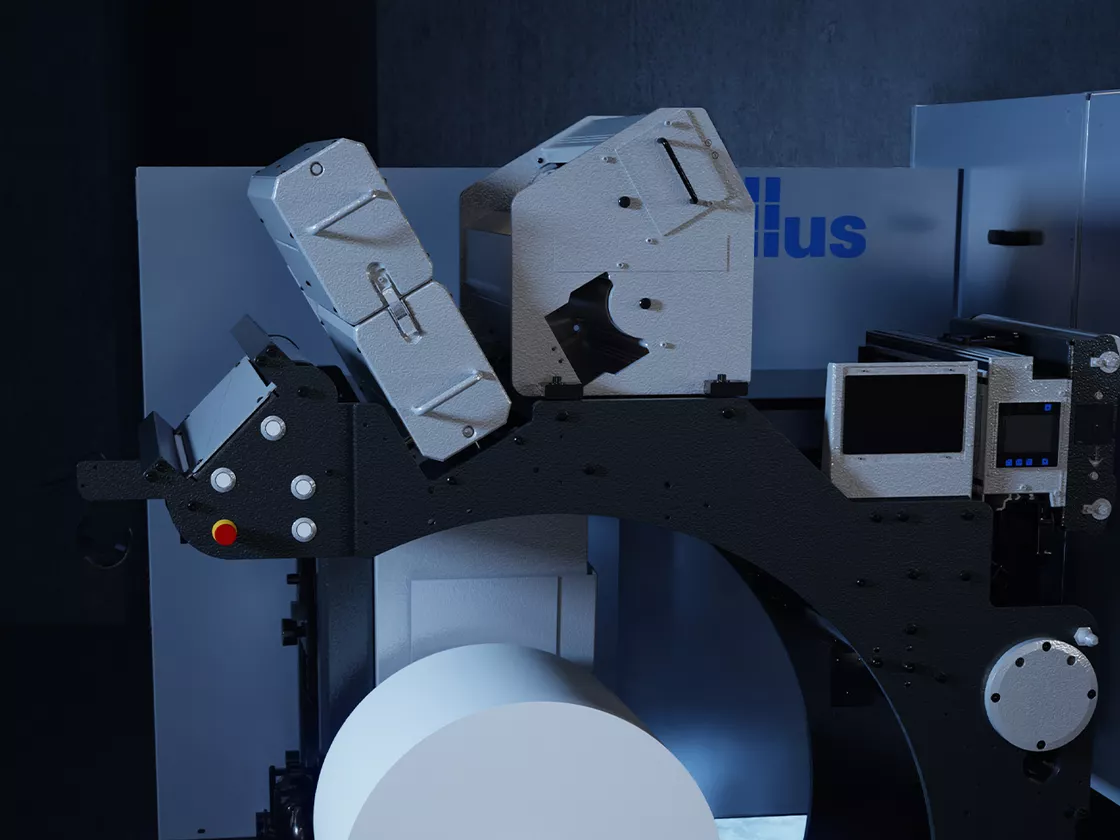

Vision System

Vision System

The Gallus One utilizes a market leading proprietary vision system, which ensures supreme print quality at all speeds and on a wide range of substrates.

- Adjusting the register setting at the push of a button

- Live visual quality checks

- Automatic compensation of missing nozzles — avoiding white lines

- Automatic compensation of density variations — avoiding rainbow effects

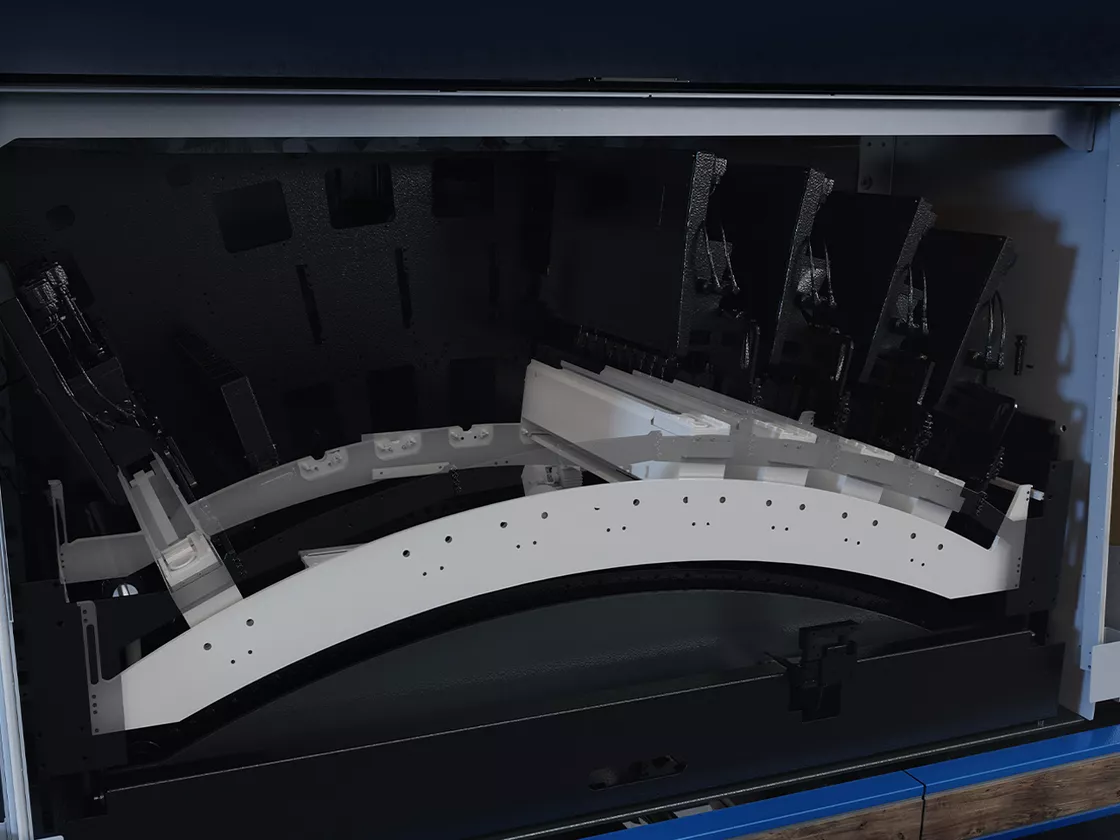

Automatic Cleaning System

Automatic Cleaning System

The Gallus One features a new, automated, automatic cleaning system that minimizes downtime and improves productivity.

- A consistent cleaning process for improved print quality

- Minimization of manual cleaning for improved press availability

- Integrated printhead covering (capping)

Automatic Splice Detection

Automatic Splice Detection

The sensors on the Gallus One automatically detect splices, letting them pass all print bars without loss of register and speed.

- Minimizing waste

- Increasing uptime

- Print remains in register

Improved Ink Handling

Improved Ink Handling

The Gallus One features a newly designed ink management system that streamlines ink replacement. What’s more, and even while the press is running, the ink cabinet is easily accessible from the operator’s side allowing ink replacement without contamination. This functionality further improves productivity and system efficiency.

Colors

CMYK

(up to 88 % PANTONE®)

White

85 % opacity

(70 m/min)

Native print resolution

1200×1200 dpi

(70 m/min)

Print width

340 mm

Productivity

1428 m²/h

It’s time to act.

Our commitment to sustainability

As a business, we recognize that there really is no time to waste in bringing sustainability to the top of the agenda. Gallus is working in alignment with HEIDELBERG’s corporate environmental program, and we are dedicated to providing the same confidence in our sustainability credentials as we achieve for every other aspect of our service.

While we are still at the start of this journey, as a first step, ensuring that our products will be carbon neutral is very important – especially in safeguarding the health and wellbeing of our children and their future generations.

Technical Specifications

Gallus One

Key Features

Key Features

- CMYK (up to 88 % PANTONE®)

- White 85 % opacity (70 m/min)

- 1200 x 1200 dpi (70 m/min)

- 340 mm printing width

- 1428 m2/h productivity

- drop freeze pinning

- automatic cleaning with ultrasonic technology

- inkjet control – vision system

- CO₂ compesated

Connections

Connections

Voltage

380-415V / 50 Hz [USA, CAN, MX optional: 480 V / 60 Hz (separate energy supply for cooling device)]

Connection power

3P + PE; Base Machine 50 A + GEW drying unit 28 A + DPU 32 A[USA, CAN, MX: transformer is required to connect Base Machine 50 A and DPU 24 A; GEW drying unit and cooling unit are connected directly to the customer’s power grid]

Compressed air

6 bar, oil- and water-free

Exhaust air

≈ 1’100 m³/h (exhaust air temperature max. 50° C / ozone output during operation)

Compliance

CE, GS (UL on request)

Remote support

Yes

Cooling system

- Air for UV-Lamp-Heads

- Air for Pinnings

- Water for electronics and web (chill roller)

Network connection

- Remote Support – Secomea for remote support

- Prinect

- GEW Support

Area Condition

Area Condition

Room temperature

20-25° C

Humidity (rel.)

40-60%

Air pressure (location)

700-1060 mbar

Evenness floor

flatness of ± 2 cm over a length of 10 m

Floor load

load-carrying capacity of 1’600 kg/m²

Dimensions

Dimensions

Machine

- Length: 6’332 mm / 250 inch

- Depth: 1’760 mm / 70 inch [with cabinet: 3’351 mm / 132 inch]

- Height: 1’857 mm / 74 inch [with exhaust air duct: 2’951 mm / 117 inch]

Workplace around the machine

- Infeed: 1’500 mm / 59 inch

- Outfeed: 1’500 mm / 59 inch

- Front: 1’500 mm / 59 inch

- Back: 1’000 mm / 39 inch [only needed without cabinet for Service]